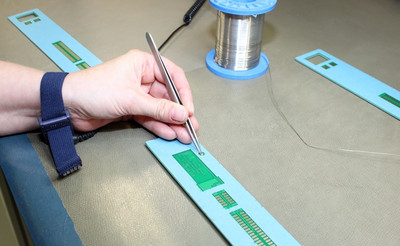

SMD – assembly

Often the target for a lot of purchasers is to reduce their number of suppliers to save expenses for administrative effort.

The Richard Wöhr GmbH offers more service and a higher added value by covering more products and services under one and the same roof.

In this case for our customers “outsourcing” means converting high fixed costs into lower variable costs. Using our services doesn’t only involve financial advantages like a lower investment need and decreasing operating costs, but also an improvement of the service quality and an increase of the adherence to schedules – especially because of our express service.

The first step during the process of SMD assembly will be realized by our fully automatic soldering paste printer. The soldering paste printer is able to take printed circuit boards with a size of 530 x 530 mm. Vector and gerber data can be provided by the customer or will be generated by our development.

With our fine pitch pick-and-place machine we are able to edit and SMD assemble printed circuit boards with a size up to 500 x 350 mm. Our SMD assembly machines has an integrated glue dispenser. The assembly of printed circuit boards is possible from the component size 0603.

In the final step during the SMD assembly the printed circuit boards will be soldered up reliable with a vapor-phase soldering system. The vapor-phase soldering system is suitable for pcbs with a maximum size of 500 x 350 mm,

but because of the vapor-phase soldering system tooling dimensions only printed circuit boards with a size of 500 x 350 mm can be SMD assembled.

The maximum size for a completely SMD assembly of pcbs is

500 x 350 mm.